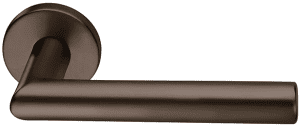

No other hardware finish is quite like oil-rubbed bronze. Its deep, rich appearance automatically lends character to any space in which it’s used.

In today’s specifications, brushed stainless steel is the most popular hardware finish. It’s like the Apple Store – bright, clean and consistent. By comparison, oil-rubbed oxidized bronze, also known as C10B or 613, is more like a university library – dark and distinguished.

If you want to take advantage of C10B’s rich character for your next project, there are a few things you should keep in mind. By being informed and having realistic expectations, you’ll be able to tell whether this finish right for your project.

Identity Crisis

First, it is important to accept that the finish is not consistent from one manufacturer to the next, or even between hardware items. The range can be anywhere from a milk chocolatey brown to almost black.

There are several factors that impact the appearance of C10B hardware.

Oxidization is a chemical process. It involves submerging metal in a chemical solution. The composition of the metal, temperature of the solution and the amount of time the material is submerged can all affect the appearance of the final product. For example, the finish will appear darker on metals with a higher the copper content.

Furthermore, material with a steel base must be electroplated with brass or bronze prior to being oxidized. Variances in this process, including cleaning, polishing and other treatments, will also impact the final finish.

Once oxidized, items are oil-rubbed. This is usually done by hand and introduces more variables that can affect the finish, like the amount of oil applied and the conditions in which it dried.

When reviewing C10B hardware samples, look for compatibility of the appearance rather than an exact match.

Here’s a tip to follow: Place samples about two feet apart and view them from a distance of three feet, rather than placing them side-by-side at arm’s length. This will give a more realistic picture of whether they will appear compatible in the field.

It's Alive!

The other big factor about this finish is that it changes over time – what some refer to as a ‘living finish’. Depending on your viewpoint, this can either be a drawback or part of the finish’s appeal.

The oil and oxidization age, wear off and react to the environment.

This effect is most drastic on hardware that is touched, like lever handles, pulls, exit devices or push plates. The acids, sweat and chemicals on users’ hands break down the oil and oxidization, exposing the brass underneath. Hardware that is not commonly touched, such as floor stops, hinges and closers, will maintain their original finish longer.

In addition, environmental factors impact the finish over time. Humidity, sunlight, temperature and exposure to the elements can all play a role in producing an aged look.

Alternatives

Where do you turn if the rich, dark look of oil-rubbed bronze is appealing, but you’re also aiming for consistency over time and across hardware types?

Don’t worry – there are solutions.

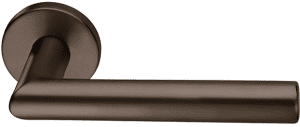

Most of the industry’s major manufacturers offer equivalent finishes that are a similar in appearance to C10B, but are powder coated, anodized or lacquered.

By taking the chemical oxidization and hand-oiling processes out of the equation, these equivalent finishes are consistent for all base metal types and won’t age like C10B.

Now that you understand the nature of oil-rubbed oxidized bronze, you can weigh the pros and cons and determine what will work best on your project.

If you need more info, we’re here to help. Just contact us with your questions.